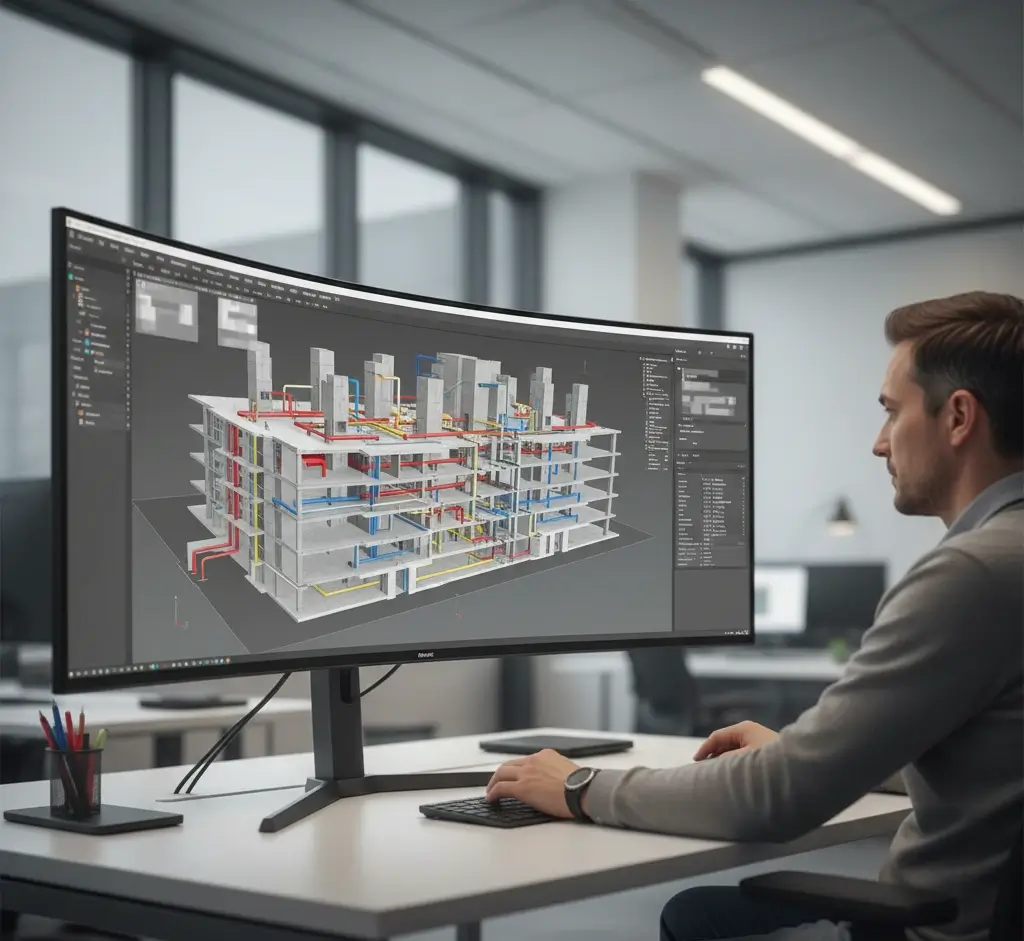

Advanced Precast Wall Detailing Solutions

Our detailing process is built on absolute clarity—each panel, embed and connection is modelled to ensure accurate fabrication and smooth on-site assembly. Every drawing set is developed with controlled coordination, reducing RFIs and giving your production team the confidence to move without delays.

From early layout development to final erection plans, our workflows are engineered for consistency and repeatability. We help contractors, fabricators and design teams eliminate guesswork, maintain quality standards and deliver projects with predictable timelines.

Our Capabilities

Panel Layout Development

We create precise shop-ready layouts that define sizes, openings and reinforcement zones with absolute clarity for production teams.

Embed & Hardware Detailing

All embeds, plates and lifting hardware are detailed with exact placement ensuring seamless casting and safe lifting operations.

Connection Engineering Support

Our detailing provides coordinated interface information for mechanical, structural and field connections across systems.

Quality & Compliance Checks

Every drawing set undergoes a multi-level review process to ensure alignment with project standards and fabrication requirements.

Our Methodology

Concept & Coordination

We start by analysing architectural and structural intents, defining panel boundaries and preparing coordinated grids.

- Panel segmentation planning

- Opening/penetration mapping

- Coordination with design teams

Panel Modelling & Reinforcement

Panel geometry, reinforcement and hardware are modelled with precision to maintain structural integrity and casting efficiency.

- Reinforcement layout

- Hardware integration

- Casting requirements

Shop Drawing Production

Detailed shop drawings are produced with consistent formatting, dimension clarity and production-focused notes.

- Marked panel drawings

- Embed detailing sheets

- QC-reviewed outputs

Erection Planning & Release

Final packages include erection sequencing, lifting guidance and coordinated connection points for smooth installation.

- Lifting/handling info

- Connection coordination

- Final submission package